Is the Haas Umc 750 Rotary Continuous

- Overview

- Details

- Specs

- Gallery

- Get Info

Standard Features

Available Options

* Not all options are compatible with each other. Some options may require the purchase of additional options, or may include additional options at no charge. Please use our Build-&-Price tool to determine option compatibility, and configure your machine.

Automation Options

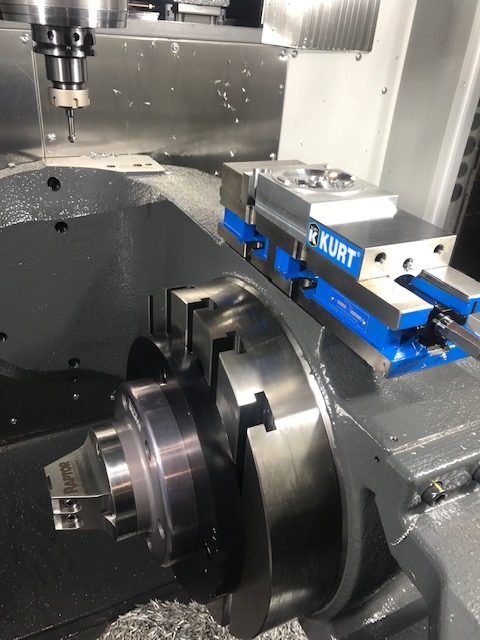

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The Haas UMC Series universal machining centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining. The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T-slots and a precision pilot bore for fixturing versatility. The trunnion provides +120 and -35 degrees of tilt and 360 degrees of rotation to provide excellent tool clearance and large part capacity.

- 5-axis simultaneous machining

- Powerful inline direct-drive spindle

- Large capacity side-mount tool changer

- Includes Wireless Intuitive Probing System

- Made in the USA

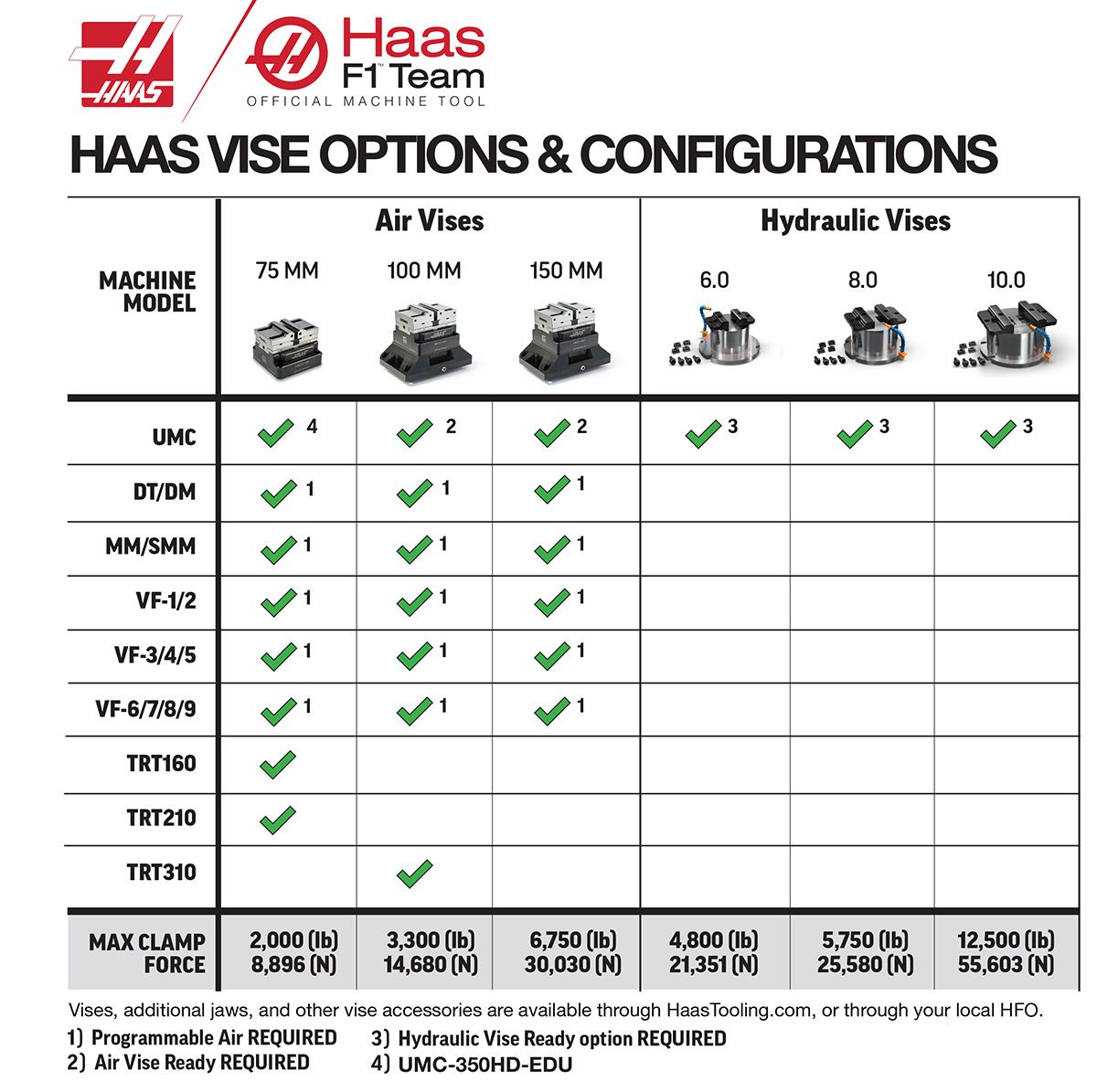

HAAS VISE OPTIONS AND CONFIGURATIONS CHART

AIR VISES | HYDRAULIC VISE | ELECTRIC VISES

L&S Machine Company

"Our company has all 5-axis machines so that we can support a variety of different industries that we're in. The reason we got into 5-axis machining is because it cuts the machining operations down; first operation can pick up five of the six sides of a part, and the final operation can pick up the final side that's bolted down to the table. Having all the same machines allows us to seamlessly schedule work between our facility and the San Jose facility, and having the same controller allows us to transfer the program to either location.

– Rob DiNardi, President

.jpg)

Skrawpol

Skrawpol Tool Factory is a modern Polish company founded in 2010. The main subject of the company's activity is the manufacturing of cutting and special tools. We have a modern machine park enabling turning and milling with high accuracy on three, four, and five axes. Our machine park includes the latest models of numerically controlled machine tools from Haas, which translates to the high quality of the tools we manufacture. We have a team consisting of qualified employees, both young people and those with many years of experience in the industry, involved in building our company.

– Paweł Zoń, Co-Owner

DesignWerkes

Our company serves the Commercial Transportation industry as well as the Aerospace industry. We design and build the power conversion system and the accessory power system for hybrid public transportation buses. For Aerospace parts, we're making parts for commercial and military avionics.

With the UMC-750, we're building five sides of the part which allows us to get to five out of those six sides that we need to build. There's also 5-axis work that needs to be done. In that part, there are ledges with radiuses in between that you can't build without the 5-axis capability.

– Steve Kille, President & Owner

Boulevard Machine & Gear

"I knew it was time to invest in technology, so in 2009 we bought our first Haas machine. The UMC-750 that we have now allows us to complete jobs that use to take 4, 5, or even 10 setups on a 3 -axis machine, in just 1 or 2 setups. This allows us to take on more work."

– Susan Kasa, President

UMC-750SS

Super-Speed 5-Axis CNC Vertical Mill with 30" x 20" x 20" travels

- 40 Taper

- 5 Axis

- 12k RPM

- 30+1 Tool Capacity

VF-5/40TR

Trunnion CNC Vertical Mill with 50" x 26" x 25" travels

- 40 Taper

- 5 Axis

- 8.1k RPM

- 30+1 Tool Capacity

UMC-1500-DUO

5-Axis Dual-Station Vertical Machining Center; 60" x 20" x 20"

- 40 Taper

- 5 Axis

- 8.1k RPM

- 30+1 Tool Capacity

WITH DWO/TCPC THERE'S NO NEED TO:

✗Place the part in the exact same location every time

✗ Repost the program when the fixture changes

✗Repost the program if the job moves to another Haas machine

DWO/TCPC CHANGES EVERYTHING:

✓Save time on programming and setup

✓ Reduce fixturing costs

✓ Increase your number of multi-axis operators

✓ Increase your productivity and profits

Overview

The UMC-750 and UMC-750SS have been redesigned to incorporate all the design improvements engineered into our larger UMC-1000 and smaller UMC-500 – completing the upgrade of our full line of 5-axis universal machining centers.

Universal Machining Center Design Improvements:

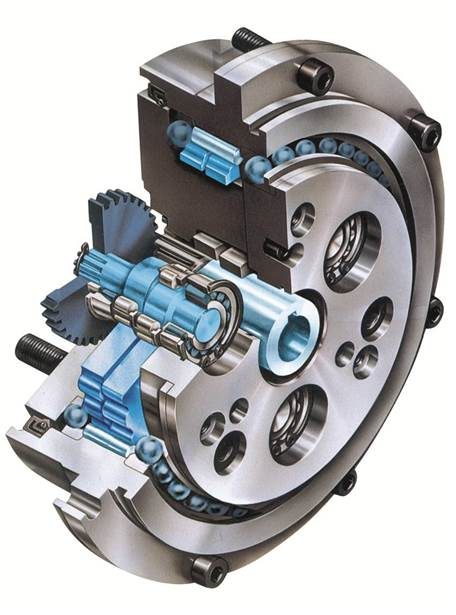

- Cycloidal rotary drives

- Lighter operator door

- Front-mounted control pendant

- Easy-access operator convenience features

- Larger side-window

- Stiffer base casting

- Standard rollaway coolant tank

Cycloidal Rotary Drives

The cycloidal rotary drive system – designed for machine tools and robotics – provides a great combination of speed, accuracy, and durability on both the B and C axes. The rugged design provides long service life, with little or no maintenance, and is especially durable in a crash. The cycloidal rotary drive can be back driven to absorb energy from an impact. The shock-load capacity is 5 times the rated torque of the gearbox, and the entire gearbox is a simple drop-in replacement, should damage occur.

Operator Door and Control Pendant

The UMC-750 door now mounts inside the enclosure, which raises the bottom of the enclosure opening, and provides better chip control. The internal mounting design of the door allows the control pendant to be mounted to the front of the machine, in an operator-friendly position.

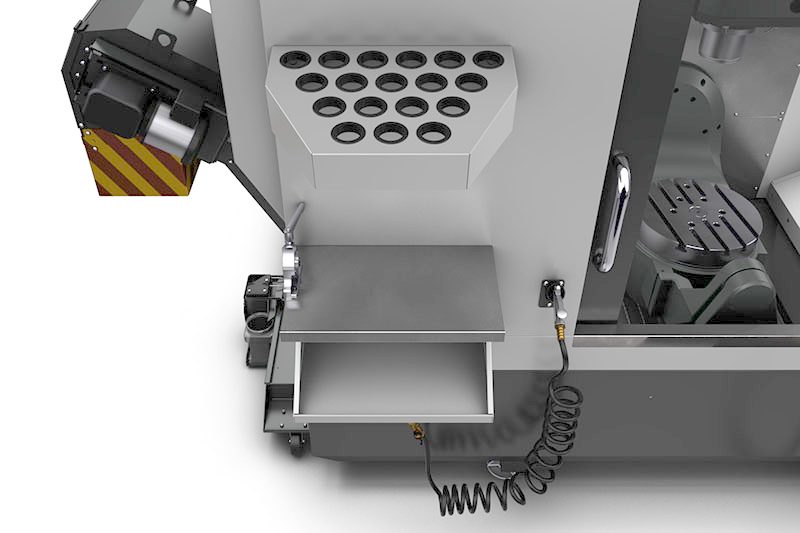

Operator Convenience Features

The UMC-750's operator convenience features are mounted to the front of the machine for easy access, including a toolholder storage rack, work table, toolholder vise, storage tray, and washdown hose.

Side-Window Design

Moving the control pendant to the front of the UMC-750 allowed us to enlarge the side window and make it slide open. This provides access to the machine's platter, and also allows a pallet pool or other automation to be added to the machine.

Base Casting and Coolant Tank

The UMC-750 base casting is stiff and compact, improving cut performance, and allowing the use of our standard 55-gallon (208 liter) rollaway coolant tank, for easy cleaning and maintenance. The coolant tank also accepts our Oil Skimmer and Coolant Refill options to further enhance productivity.

| Travels | S.A.E | METRIC |

|---|---|---|

| X Axis | 30.0 in | 762 mm |

| Y Axis | 20.0 in | 508 mm |

| Z Axis | 20.0 in | 508 mm |

| Spindle Nose to Platter (~ max) | 24.0 in | 610 mm |

| Spindle Nose to Platter (~ min) | 4.0 in | 102 mm |

| Spindle | S.A.E | METRIC |

|---|---|---|

| Max Rating | 30.0 hp | 22.4 kW |

| Max Speed | 8100 rpm | 8100 rpm |

| Max Torque | 90.0 ft-lbf @ 2000 rpm | 122.0 Nm @ 2000 rpm |

| Drive System | Inline Direct-Drive | Inline Direct-Drive |

| Taper | CT40 | BT40 | HSK-A63 | CT40 | BT40 | HSK-A63 |

| Bearing Lubrication | Air / Oil Injection | Air / Oil Injection |

| Cooling | Liquid Cooled | Liquid Cooled |

| B Axis - Tilt | S.A.E | METRIC |

|---|---|---|

| Travel | 120 ° to 35- ° | 120 ° to 35- ° |

| Max Speed | 50 °/sec | 50 °/sec |

| Max Torque | 2240 ft-lbf | 3037 Nm |

| Brake Torque | 2000 ft-lbf | 2712 Nm |

| C Axis - Rotation | S.A.E | METRIC |

|---|---|---|

| Travel | 360 ° | 360 ° |

| Max Speed | 50 °/sec | 50 °/sec |

| Max Torque | 1854 ft-lbf | 2514 Nm |

| Max Part Swing | 27.0 in | 686 mm |

| Brake Torque | 900 ft-lbf | 1220 Nm |

| Platter | S.A.E | METRIC |

|---|---|---|

| Platter Diameter | 19.70 in | 500 mm |

| Max Weight on Platter | 660 lb | 300.0 kg |

| T-Slot Width | 0.626 in to 0.630 in | 15.90 mm to 16.00 mm |

| T-Slot Center Distance | 2.48 in | 63 mm |

| Number of Std T-Slots | 7 | 7 |

| Feedrates | S.A.E | METRIC |

|---|---|---|

| Max Cutting | 650 ipm | 16.5 m/min |

| Rapids on X | 900 ipm | 22.9 m/min |

| Rapids on Y | 900 ipm | 22.9 m/min |

| Rapids on Z | 900 ipm | 22.9 m/min |

| Axis Motors | S.A.E | METRIC |

|---|---|---|

| Max Thrust X | 2750 lbf | 12233 N |

| Max Thrust Y | 2750 lbf | 12233 N |

| Max Thrust Z | 3400 lbf | 15124 N |

| Tool Changer | S.A.E | METRIC |

|---|---|---|

| Type | SMTC | SMTC |

| Capacity | 30+1 | 30+1 |

| Max Tool Diameter (full) | 2.5 in | 64 mm |

| Max Tool Diameter (adjacent empty) | 5.0 in | 127 mm |

| Max Tool Length (from gage line) | 12 in | 305 mm |

| Max Tool Weight | 12 lb | 5.4 kg |

| Tool-to-Tool (avg) | 2.8 s | 2.8 s |

| Chip-to-Chip (avg) | 3.6 s | 3.6 s |

| General | S.A.E | METRIC |

|---|---|---|

| Coolant Capacity | 55 gal | 208 L |

| Air Requirements | S.A.E | METRIC |

|---|---|---|

| Air Required | 4 scfm @ 100 psi | 113 L/min @ 6.9 bar |

| Inline Air Hose | 3/8 in | 3/8 in |

| Coupler (Air) | 3/8 in | 3/8 in |

| Air Pressure Min | 80 psi | 5.5 bar |

| Dimensions - Shipping | S.A.E | METRIC |

|---|---|---|

| Domestic Pallet | 168 in x 93 in x 110 in | 427 cm x 235 cm x 280 cm |

| Export Pallet | 174 in x 92 in x 100 in | 442 cm x 234 cm x 254 cm |

| Weight | 14250 lb | 6463.8 kg |

| Electrical Specification | S.A.E | METRIC |

|---|---|---|

| Spindle Speed | 8100 rpm | 8100 rpm |

| Drive System | Inline Direct-Drive | Inline Direct-Drive |

| Spindle Power | 30.0 hp | 22.4 kW |

| Input AC Voltage (3 Phase) - Low | 220 VAC | 220 VAC |

| Full Load Amps (3 Phase) - Low | 70 A | 70 A |

| Input AC Voltage (3 Phase) - High* | 440 VAC | 440 VAC |

| Full Load Amps (3 Phase) - High* | 35 A | 35 A |

*Haas machines are designed to operate on 220 VAC power. An optional internal high-voltage transformer (380 - 480 VAC) is available for all models, except the Desktop Mill, CL-1, and CM-1. This optional high-voltage internal transformer is not field installable; it must be ordered with the machine.

ATTENTION! Optional high-performance spindles have a higher power requirement than the standard spindle. Verify the power requirement before running power for your machine.

Source: https://www.haascnc.com/machines/vertical-mills/universal-machine/models/umc-750.html

0 Response to "Is the Haas Umc 750 Rotary Continuous"

Post a Comment